The advancement of digital technologies has transformed the manufacturing sector, enabling industries to operate more efficiently and effectively. One of the key enablers of this transformation is edge computing. As defined by Enterprise Talk, Edge Computing is a decentralized approach to data processing and storage that allows devices to process data locally, thereby reducing latency and improving response times. This innovative approach has numerous benefits, including enhanced real-time data analysis, improved decision-making capabilities, and increased operational efficiency.

In the manufacturing context, edge computing can significantly enhance industrial automation, enabling faster and more accurate processing of data from sensors, cameras, and other devices. By processing data closer to its source, it reduces the need for large centralized data centers, thereby lowering costs and improving security. As highlighted by STL Partners, it offers numerous use cases in manufacturing, including predictive maintenance, quality control, and supply chain optimization. With its potential to revolutionize the way industries operate, this is poised to unlock new levels of efficiency and automation in the manufacturing sector.

The Rise of Edge Computing in Manufacturing: Unlocking Efficiency and Automation

Edge computing has revolutionized the manufacturing sector by providing real-time data processing and decision-making capabilities closer to the source of data. This shift from centralized computing to distributed and allows manufacturers to process and analyze vast amounts of data at the edge of their networks, leading to significantly enhanced operational efficiency and automation. In this blog, we will delve into the benefits, challenges, and use cases of edge computing in industrial automation and manufacturing.

What is Edge Computing?

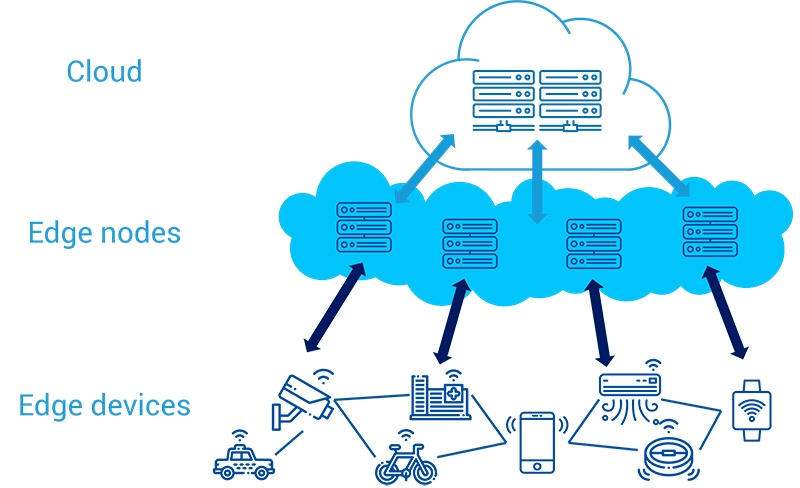

Edge computing refers to the processing of data near its source, rather than relying on cloud-based or centralized data centers. This approach enables faster processing times, reduced latency, and improved privacy and security. For manufacturers, it provides a number of advantages that contribute to increased efficiency and automation.

Benefits of Edge Computingn Manufacturing

1. Real-Time Data Analysis

Edge computing allows for real-time data analysis, which is crucial for manufacturing processes that require quick decision-making. With this, data is processed and analyzed at the source, enabling faster and more accurate responses to trends and anomalies.

2. Improved Operational Efficiency

By moving data processing closer to the source, manufacturers can reduce the time spent on data transmission, processing, and analysis. This leads to increased operational efficiency and reduced downtime.

3. Enhanced Cybersecurity

Edge computing allows for data to be processed and stored locally, reducing the risk of data breaches and cyberattacks. This local processing also ensures that sensitive data does not leave the premises, enhancing overall security.

4. Increased Scalability

Edge computing enables manufacturers to scale their operations more easily by distributing processing power across multiple locations. This flexibility is particularly useful for companies with distributed production facilities or those that need to handle peak demand.

Challenges in Manufacturing

1. Implementation Costs

Deploying edge computing infrastructure can be expensive, especially for larger or more complex manufacturing operations. Manufacturers need to account for the initial investment in hardware and software, as well as ongoing maintenance and support costs.

2. Integration Challenges

Integrating edge computing solutions with existing infrastructure can be complex, requiring significant technical expertise and resources. Manufacturers must ensure seamless integration with their existing IT systems and processes.

3. Data Management

Managing the vast amounts of data generated by edge computing devices can be a significant challenge. Manufacturers must develop strategies for data storage, backup, and retrieval to maximize the benefits of edge computing.

Use Cases in Industrial Automation and Manufacturing

1. Predictive Maintenance

Edge computing enables predictive maintenance by analyzing sensor data in real-time. This allows manufacturers to proactively schedule maintenance and reduce downtime, leading to increased efficiency and productivity.

2. Quality Control

Edge computing can be used to monitor and control the quality of products in real-time. By processing data at the source, manufacturers can detect and correct defects earlier, improving overall product quality.

3. Supply Chain Optimization

Edge computing can help optimize supply chain operations by providing real-time visibility into inventory levels, order fulfillment, and logistics. This enables manufacturers to adjust their supply chain strategies dynamically and reduce delays.

Future in Manufacturing

Edge computing is poised to play a significant role in the future of manufacturing. As the volume and complexity of data continue to grow, edge computing will become increasingly important for real-time decision-making and operational efficiency. Advances in AI, ML, and IoT technologies will further enhance the capabilities of edge computing, enabling more sophisticated automation and optimization.

What’s Next?

As edge computing becomes more prevalent in manufacturing, companies will need to adapt their strategies to maximize the benefits. This includes investing in the necessary infrastructure, training personnel, and developing robust data management systems. By embracing edge computing, manufacturers can unlock new levels of efficiency, automation, and competitiveness in a rapidly evolving market.

By leveraging edge computing, manufacturers can transform their operations, improve their competitive edge, and drive innovation. As the technology matures and becomes more accessible, we can expect to see even more widespread adoption across various industries.

You may also be interested in: About | Corvalent

Ready to elevate your mission-critical operations? From medical equipment to military systems, our USA-built Industrial Computing solutions deliver unmatched customizability, performance and longevity. Join industry leaders who trust Corvalent’s 30 years of innovation in industrial computing. Maximize profit and performance. Request a quote or technical information now!