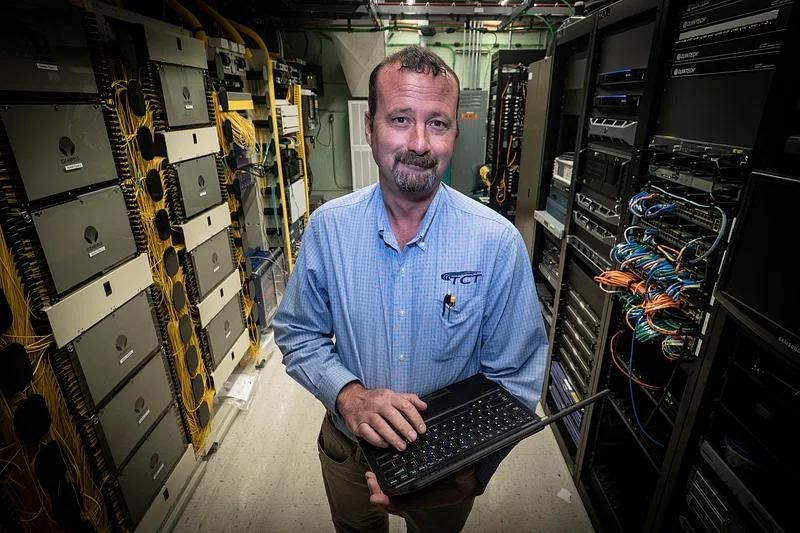

The industrial world relies heavily on the reliability and performance of its computer systems. Servers and PCs are the backbone of many industrial operations, from manufacturing to logistics, and their ability to function seamlessly under demanding conditions is crucial. However, not all servers and PCs are created equal. Industrial servers and PCs are specifically designed to meet the exacting standards of these environments, ensuring that they can withstand extreme temperatures, humidity, and vibrations that would render ordinary computers useless. These specialized systems are engineered to operate continuously, 24/7, without compromising on performance or reliability.

Industrial servers and PCs are built to withstand the rigors of industrial environments, where downtime can be costly and hazardous. They are designed to operate in temperatures ranging from -40°C to 70°C, and in environments where humidity can reach 95%, ensuring that they can function reliably in even the most extreme conditions. Moreover, they are built to withstand high levels of vibration and shock, making them ideal for use in transportation, manufacturing, and other sectors where equipment is subject to rough handling.

Industrial servers and PCs are not just about performance and reliability; they are also designed to be easy to maintain and upgrade. Their compact and rugged designs make them easy to install and integrate into existing systems, and their modular nature allows for rapid upgrades and repairs. This ensures that businesses can quickly respond to changing market conditions and technological advancements without incurring significant downtime or disruption to their operations.

Industrial servers and PCs are engineered to meet the specific demands of industrial environments, providing the reliability and performance that these sectors require. From manufacturing to logistics, these systems are the backbone of modern industry, ensuring that operations run smoothly and efficiently.

When it comes to ensuring the stability and continued operations of critical systems, industrial servers and PCs are the backbone of modern manufacturing and industry. Unlike consumer-grade computers, these specialized machines are designed to withstand harsh environments, handle heavy workloads, and maintain reliability even under the most demanding conditions. In this blog, we will delve into the key features and benefits of industrial servers and PCs, exploring why they are the preferred choice for industries that require high-performance computing solutions.

Key Features of Industrial Servers and PCs

1. Durability and Reliability

Industrial servers and PCs are built to withstand harsh environmental conditions such as extreme temperatures, humidity, and vibrations. They are engineered to operate efficiently and without failures, ensuring continuous production and minimal downtime. This durability is achieved through rigorous testing and the use of high-quality materials that can withstand the rigors of industrial use. For example, Thomas-Krenn’s industrial PCs are designed to operate in temperatures ranging from -20°C to 60°C, making them suitable for a wide range of applications, from factory floors to outdoor environments.

2. High Performance

Industrial servers and PCs are designed to handle demanding tasks such as real-time data processing, complex simulations, and high-throughput data transmissions. They are equipped with powerful processors, high-capacity storage, and advanced graphics capabilities. These systems can handle heavy workloads and multiple applications simultaneously, ensuring smooth operations and efficient resource utilization. For instance, ACNode’s industrial computers are equipped with the latest Intel processors and high-speed communication interfaces, making them ideal for applications requiring high-speed data processing and transmission.

3. Security and Data Protection

Industrial servers and PCs are designed with security and data protection in mind. They are equipped with robust security features such as encryption, firewalls, and secure boot capabilities. These measures protect against cyber threats and ensure that critical data remains secure. Additionally, these systems often come with advanced monitoring and management tools, allowing for remote monitoring and maintenance, which is essential for industries that require 24/7 operations. OnLogic’s edge computers, for example, feature robust security features and are designed to be managed remotely, making them suitable for applications in industries such as manufacturing, logistics, and healthcare.

4. Customization and Flexibility

Industrial servers and PCs are often customizable to meet the specific needs of an industry or application. This customization can include tailored hardware configurations, software integrations, and specialized interfaces. For example, an industrial PC designed for a specific manufacturing process might include specialized sensors and controllers, while another designed for a logistics application might include advanced GPS and communication modules. This customization allows for seamless integration with existing systems and ensures that the industrial server or PC meets the exact requirements of the application.

Applications of Industrial Servers and PCs

1. Industrial Automation

Industrial servers and PCs are widely used in industrial automation, where they control and monitor machines, processes, and equipment. They are used in a variety of applications, including robotics, machine vision, and predictive maintenance. In these applications, the reliability and performance of the industrial server or PC are critical to ensuring continuous operations and minimizing downtime.

2. Data Analytics and Processing

Industrial servers and PCs are also used in data analytics and processing, where they handle large volumes of data from sensors, cameras, and other sources. They are used in applications such as predictive maintenance, quality control, and supply chain management. In these applications, the high processing power and reliability of industrial servers and PCs are essential for real-time data processing and analysis.

3. Edge Computing

Industrial servers and PCs are also used in edge computing, where they process data locally rather than sending it to the cloud. This approach is beneficial in applications where data needs to be processed quickly and securely, such as in real-time monitoring and control of industrial processes. Edge computing also reduces the latency and bandwidth requirements associated with cloud-based processing, making it a more efficient and cost-effective solution for many industries.

The Future of Industrial Servers and PCs

The future of industrial servers and PCs is bright, with continued advancements in technology and applications. The increasing adoption of Industry 4.0 and the Internet of Things (IoT) will drive the demand for more advanced and specialized industrial computing solutions. The integration of AI and machine learning will also enhance the capabilities of these systems, enabling more accurate predictions and real-time decision-making.

Industrial servers and PCs are the backbone of modern industry and manufacturing. Their durability, high performance, security, and customization make them the preferred choice for applications requiring reliable and efficient computing solutions. As technology continues to evolve, we can expect even more advanced and specialized industrial computing solutions to emerge, further enhancing the capabilities and applications of these critical systems.

You may also be interested in: Rackmount Server Class Machines | Corvalent

Ready to elevate your mission-critical operations? From medical equipment to military systems, our USA-built Industrial Computing solutions deliver unmatched customizability, performance and longevity. Join industry leaders who trust Corvalent’s 30 years of innovation in industrial computing. Maximize profit and performance. Request a quote or technical information now!